Clarification of turbid solutions is a key requirement to achieve critical objectives in the pharmaceutical and bio-pharmaceutical manufacturing which range from clarification, polishing, bio-burden reduction to sterilization of process fluids.

These process streams can range from easy to filter, predictable solutions such as large volume parenteral, water for injection and buffers, to difficult to filter colloidal solutions, emulsions, liposomal drug delivery systems, cell cultures, lysates, plasma, etc.

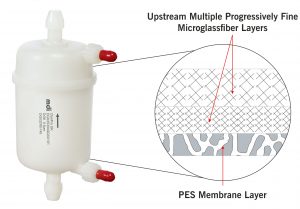

0.2 µm Membrane filters are used at various stages of the manufacturing process and fluids with a wide ranging contamination profile, including difficult to filter colloids and compressible particles, pose a serious challenge to these filters. This leads to lower throughputs and higher filtration footprint.