Quality Assurance

Quality Management System

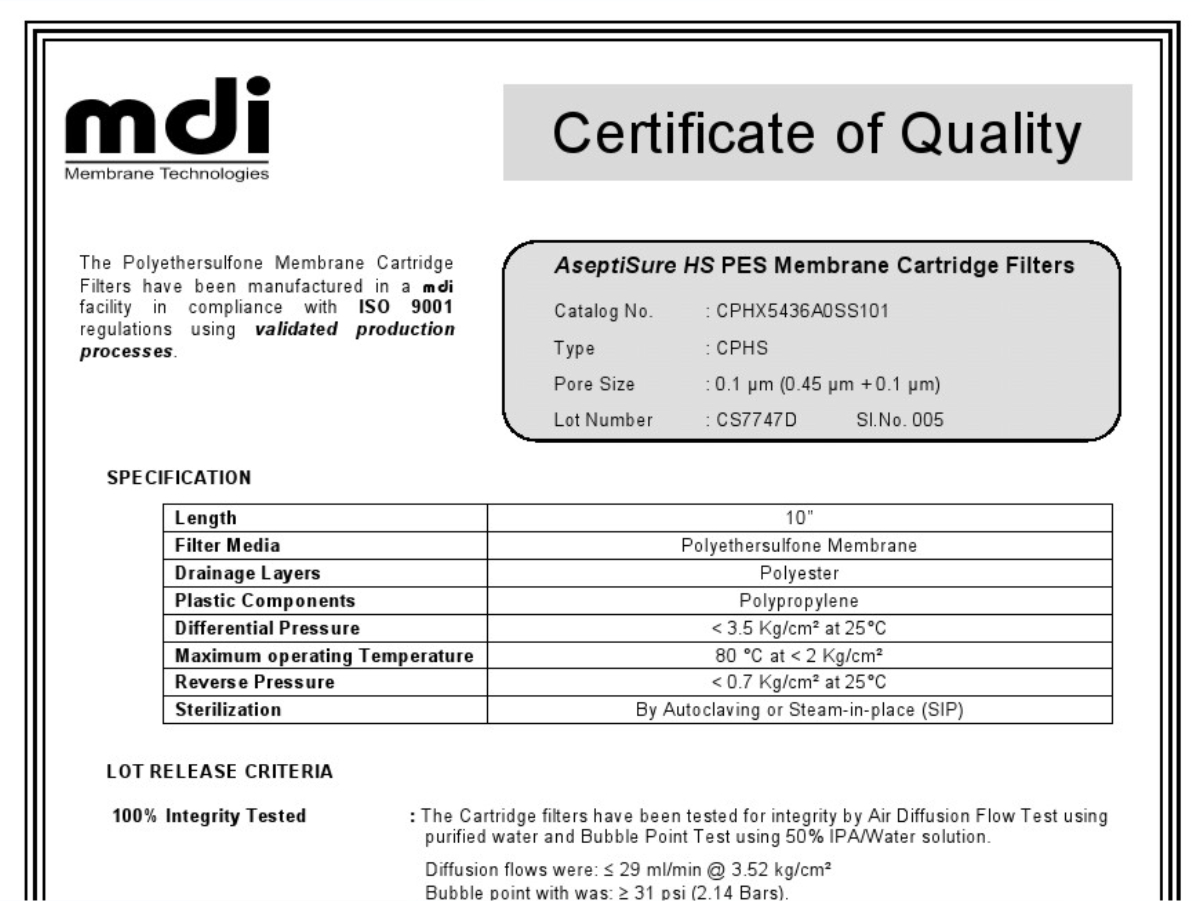

MDI Single Use Systems are well designed products with in-built quality assurance. ISO-9001 Certified Quality Management System, careful selection of raw materials, validated production processes and testing procedures based on international standards and guidelines such as CFR, PDA, and ASTM, ensures manufacture of consistently high quality assemblies.

Validation

Validation at MDI is an integral part of product and process development. As per Bio-Process Systems Alliance (BPSA) guidelines and standards committee document and component quality test matrices for SUS, a wide range of physical, chemical, biological, and functional tests are to be conducted to qualify and validate various product specifications and ensure compliance.

Since SUS are used for aseptic transfer, storage and transport of fluids in biopharmaceutical processes, their validation has been carried out to provide detailed evidence of compliance with regulatory as well critical process requirements with regard to sterility, microbial recovery, endotoxins, biosafety, extractables, product integrity, packaging and transportation. These validations have been designed basedon various regulatory and industry standards and guidelines such as USP, ISO, ASTM and CFR.