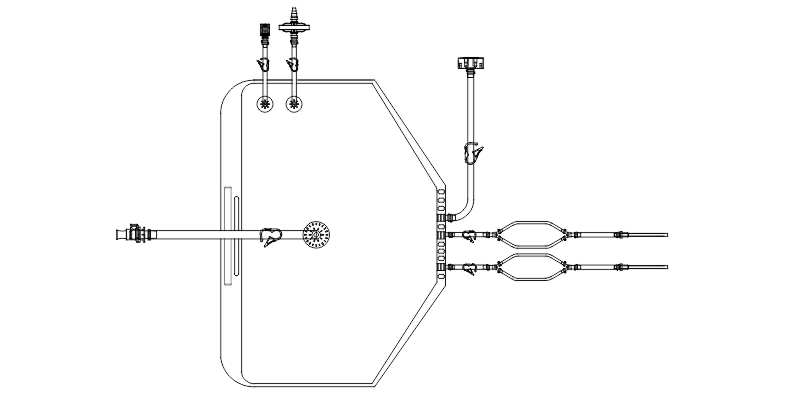

- Disposable filling lines for final fill and finish of high value drug products.

| Physical Properties of Film | |

| Storage Temperature | -20°C to 45°C |

| Materials of Construction | |

| Bag Film | AseptiFlex™ D film |

| Operational | |

| Sterilization | Gamma Sterilizable upto 50 kGy |

| Assurance | |

| 100% Integrity Tested | Each AseptiBag™ HV is tested for integrity to comply with validated Acceptable Integrity Test Specifications. |

| Bacterial Endotoxin | Aqueous extracts exhibit < 0.25 EU/ml as established by Limulus Amebocyte Lysate (LAL) Test as per USP <85> |

| Bioburden | Device bioburden is tested as per ISO 117 37-1 and assured to be <1000 cfu/bag. |

| Fiber Release | Passes microscopic test for fibers |

| Particle Release | Complies with USP <788> test for particulate matter in injections |

| Endotoxin Testing | Aqueous extracts exhibit <0.125 EU/ml as established by Limulus Amebocyte Lysate (LAL) Test as per USP <85> |

| Extractables | The Extractable study was performed as per Biophorum Best Practices Guide for Extractable Testing of Polymeric Single-Use Components used in Biopharmaceutical Manufacturing. |

| Sterility | The gamma sterilization process has been validated as per ISO 11137 to ensure a sterility assurance level (SAL) of 10-6 |

| Biosafety |

Passes the Biological Reactivity Tests, In Vivo for Class VI plastics as described in USP <88>.

Passes the Biological Reactivity Tests, In Vitro for Cytotoxicity as described in USP <87>.

|

MDI AseptiBag™ HV is only available as part of mdi single use systems

| File Type | Download |

|---|---|

| Datasheet | Download |

Have questions or need assistance?

Our team is here to help! Contact us today, and we’ll get back to you as soon as possible.