AseptiBag™ HT

MDI AseptiBag™ HT are well characterized and validated for integrity and strength, sterility, microbial ingress, endotoxins, biosafety, extractables, particulate matter that may impact the identity, strength, quality and purity of the samples.

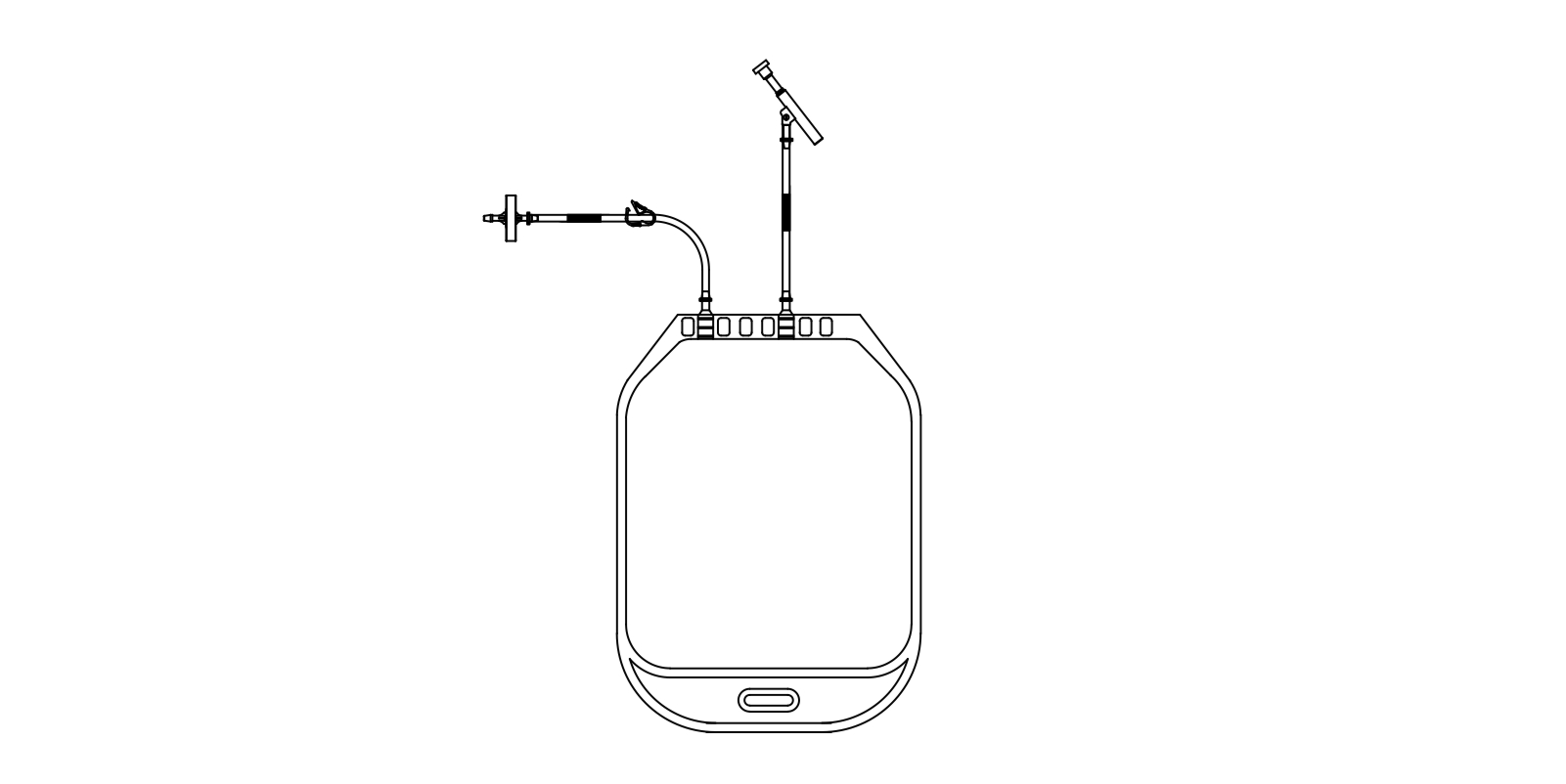

MDI ASESS sampling systems with autoclavable AseptiBag™ HT bags are designed to withstand autoclaving temperatures (121°C-123°C) and offer a reliable solution for such applications.

Aseptic sampling from lab scale table top reusable bioreactors is a challenge. Reusable sampling containers connected to the bioreactor are prone to damage during autoclaving, resulting in leakages and expensive downtime.

mdi AseptiBag™ HT sampling bags are used for sampling from reusable bioreactors in clone selection and media optimization labs

| Film | High Density Polyethylene (HDPE) |

| Tensile Strength | 19265.3 N/sq. inch |

| Tear Strength | Transverse Direction (TD): 19.38 N/inch

Machine Direction (MD): 22.8 N/inch |

| Puncture Resistance | 5.50 N/sq. inch |

| Seal Strength | 3197.5 N/sq. inch |

| Sterilization | By Autoclaving: Autoclavable at 121°C for 30 minutes

By Gamma Irradiation: Gamma Sterilizable upto 50 kGy |

| Bacterial Endotoxin | Aqueous extracts exhibit < 0.25 EU/ml as established by Limulus Amebocyte Lysate (LAL) Test as per USP <85> |

| Sterility Assurance | The sterilization dose of 25 kGy has been substantiated through careful definition of the test samples, bio-burden testing of multiple lots of the selected test samples, calculation of verification dose and sterility testing.

mdi AseptiBag™ HT sampling bags are sterilized by gamma irradiation to provide a sterility assurance level of 10-6. The sterilization process has been validated as per ISO 11137-2 which includes dose verification, dose mapping and quarterly dose audits. |

| 100% Integrity Tested | Each AseptiBag™ HT sampling bags are tested for integrity to comply with validated Acceptable Integrity Test Specifications. |

| Pressure Endurance | AseptiBag™ HT sampling bags are validated to endure operating pressure and burst pressure with liquid to ensure user as well as product safety in case of inadvertent pressure build-up. |

| Temperature Endurance | AseptiBag™ HT sampling bags are validated to withstand autoclaving temperatures up to 121°C. |

| Bioburden Testing | Bioburden is tested as per ISO 117 37-1 and assured to be <1000 cfu/bag. |

| Biosafety | Passes Biological Reactivity test, In-Vivo, as per USP <88> for Class VI plastics.

Passes the Biologic al Reactivity Tests, In Vitro for Cytotoxicity as described in USP <87>. |

| Extractables | Extractables/leachables from bags, used at various stages of a biopharmaceutical manufacturing process, will add on and may impact the impurity profile of the desired product. |

| Particulate Matter | AseptiBag™ HT sampling bags are validated for particulate matter in injections as per USP <788>.

These are also validated for visible particulates in injections as per USP <790>. |

| File Type | Download |

|---|---|

| Datasheet | Download |

Have questions or need assistance?

Our team is here to help! Contact us today, and we’ll get back to you as soon as possible.