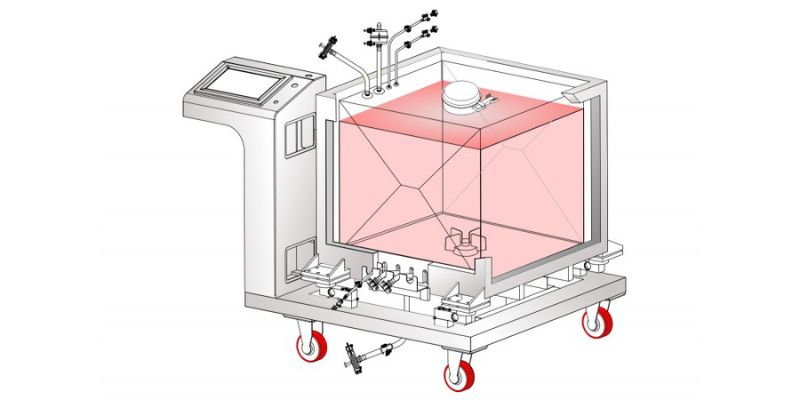

AseptiMix™ MI

MDI AseptiMix™ MI 3D mixer bags provide validated and reliable mixing solutions for biopharmaceutical process requirements such as mixing of

- Cell culture media

- Process intermediates

- Sterile buffers with wide ranging pH

- Formulations

MDI AseptiMix™ MI single use mixer bags are designed for uniform and fast mixing. The impeller is located inside the AseptiMix™ MI mixer bags which is rotated with the help of a magnetic drive. These are available for volumes upto 3000 liters.

Powder Ports

The AseptiMix™ MI mixer bag is also available with 4” and 8” sanitary flange powder ports for powder-to-liquid mixing.

- Custom designed to suit user specific process applications

- Impeller for uniform and easy mixing

- Available with 4” and 8” sanitary flange powder port for powder-to-liquid mixing

- Easy inlet and outlet quick connections

- High barrier properties for protection of product molecule, product pool and media components

- 100% integrity tested

- Powder to liquid mixing

- Liquid to liquid mixing

| Materials of Construction | |||||||||||||||||||||||||||||||||

| Impeller | Polypropylene | ||||||||||||||||||||||||||||||||

| Bag Film | AseptiFlex-I | ||||||||||||||||||||||||||||||||

| Tubing |

|

||||||||||||||||||||||||||||||||

| Dimensions | |||||||||||||||||||||||||||||||||

| Bag Size |

|

||||||||||||||||||||||||||||||||

| Assurance | |||||||||||||||||||||||||||||||||

| Bacterial Endotoxin | Aqueous extracts exhibit < 0.25 EU/ml as established by Limulus Amebocyte Lysate (LAL) Test as per USP <85> | ||||||||||||||||||||||||||||||||

| Fiber Release | Passes test as per USP and comply with USFDA 21 CFR Part 210.3(b)(6) for fiber release | ||||||||||||||||||||||||||||||||

| Particle Release | Complies with USP <788> test for particulate matter in injections | ||||||||||||||||||||||||||||||||

| Extractables with WFI | Does not affect the quality of Water for Injection (passes tests as per USP <661>) | ||||||||||||||||||||||||||||||||

| Sterilization | Gamma Sterilizable upto 50 kGy | ||||||||||||||||||||||||||||||||

| Sterility | The gamma sterilization process has been validated as per ISO 11137 to ensure a sterility assurance level(SAL) of 10-6 | ||||||||||||||||||||||||||||||||

| Biosafety | Passes the Biological Reactivity Tests, In Vivo for Class VI plastics as described in USP <88>. | ||||||||||||||||||||||||||||||||

These AseptiMix™ MI mixing systems can be customized to suit user requirements regarding tubing sizes, type of inlet ports, sampling ports, and position and type of drain ports. A technical feasibility of the required design is established based on available components and an initial drawing is proposed. Products prototyping and final approval leads to customized mixer bag realization.

| File Type | Download |

|---|---|

| Datasheet | Download |

Have questions or need assistance?

Our team is here to help! Contact us today, and we’ll get back to you as soon as possible.