MDI ASESS Aseptic Sampling System is designed for sampling biopharmaceuticals and other process fluids for analytical purposes such as:

- Bio-burden

- Endotoxin

- Sterility Testing

- pH Testing

- Chemical Analysis

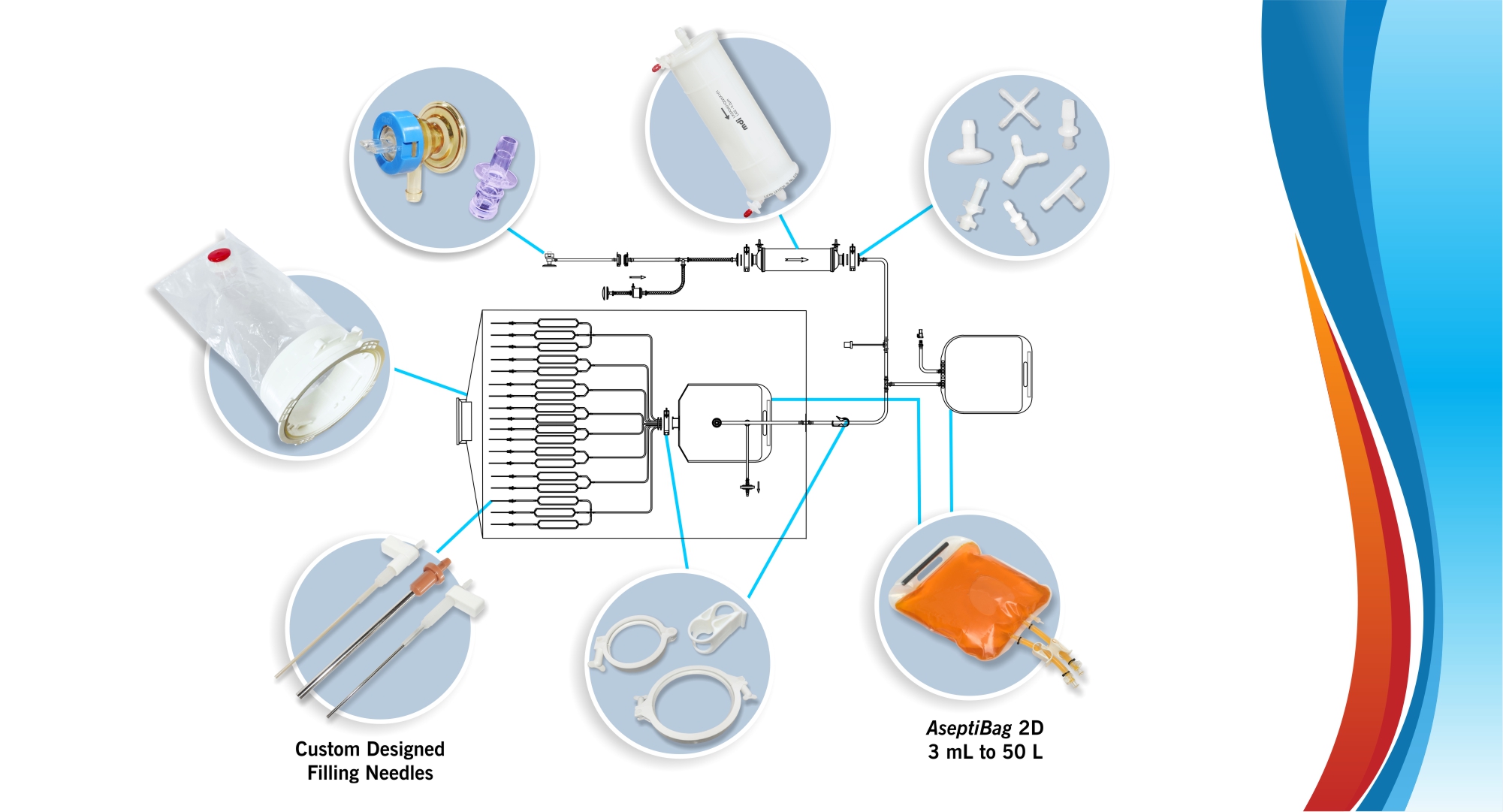

The Aseptic Closed Sampling Systems are used to achieve multiple sampling from sterile containers such as process vessels and bioreactors while complying with regulatory guidelines

Unique Features:

- Closed system: Prevents extraneous contamination

- Artifacts free clean system

- Personnel safety from biohazardous and cytotoxic fluids

- Cost advantage through customization

- Easy and aseptic sampling for different tests

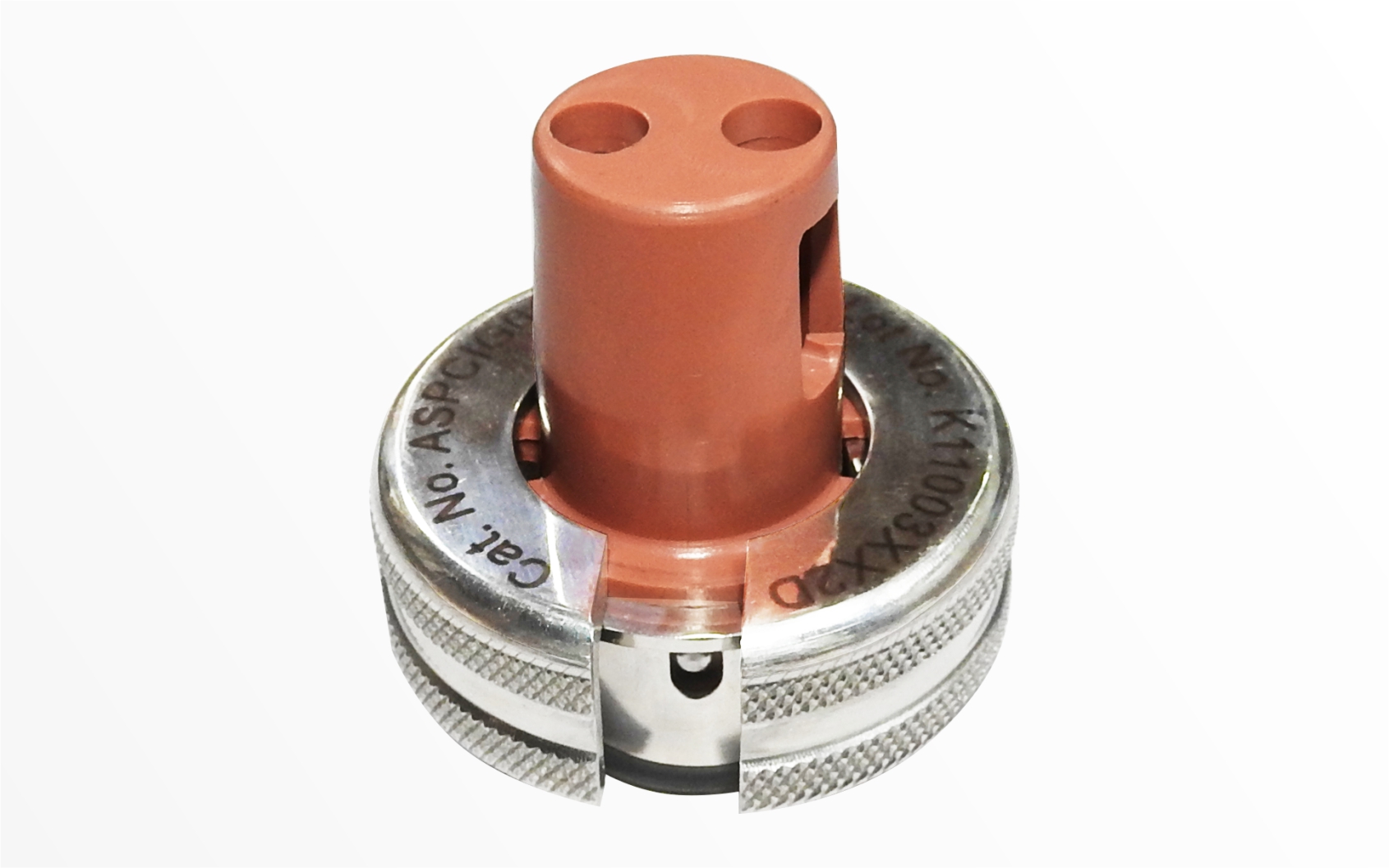

Asess sampling port is available with the following needles:

Customization:

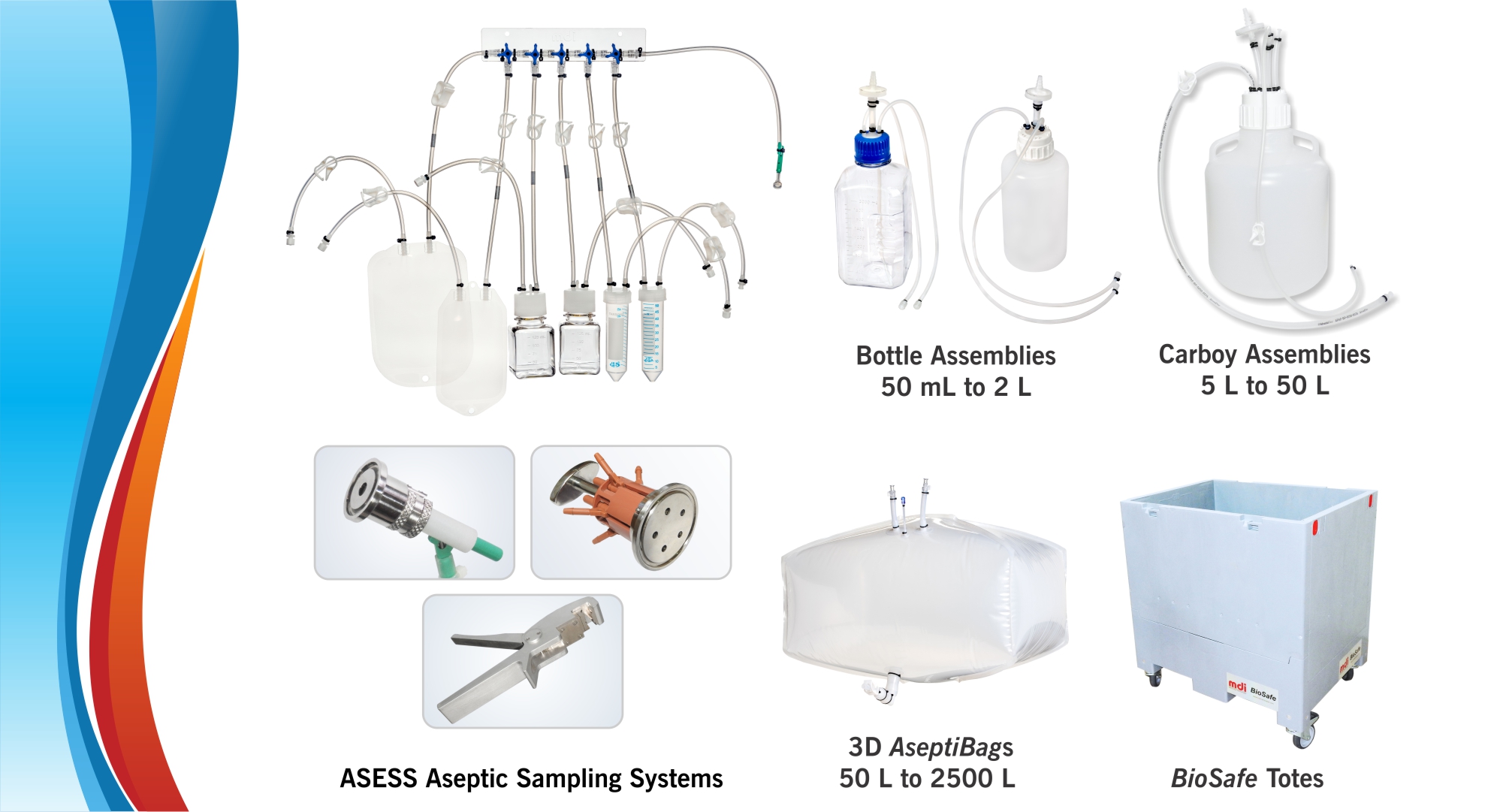

ASESS Aseptic Sampling Systems can be customized to suit user requirements regarding the number and type of sampling containers such as bags, bottles, and centrifugal tubes.

A technical feasibility of the required design is established based on available components and an initial drawing is proposed. Product prototyping and final approval leads to customized system realization.