MDI AseptiWave pre-sterilized and disposable bioreactors are designed for efficient cell culture of all cell types including Mammalian cells, Plant cells, Insect cells, Microbial cells, Stem cells, etc.

These are available gamma sterilized, in multiple sizes ranging from 2 liters for clone selection and media optimization labs, up to 50 liters for process development as well as GMP production of biopharmaceuticals.

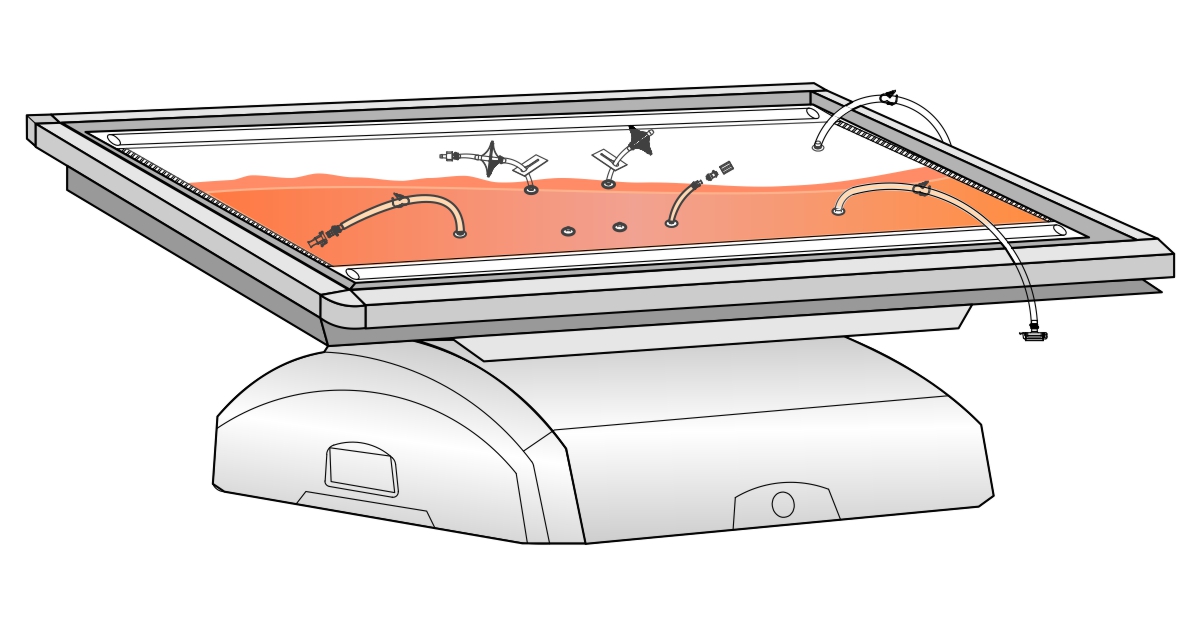

The bag is placed on any wave inducing rocker base unit/bioreactor system that induces the waves in the cell culture fluid inside the bag through the rocking motion to provide efficient mixing and gas transfer.

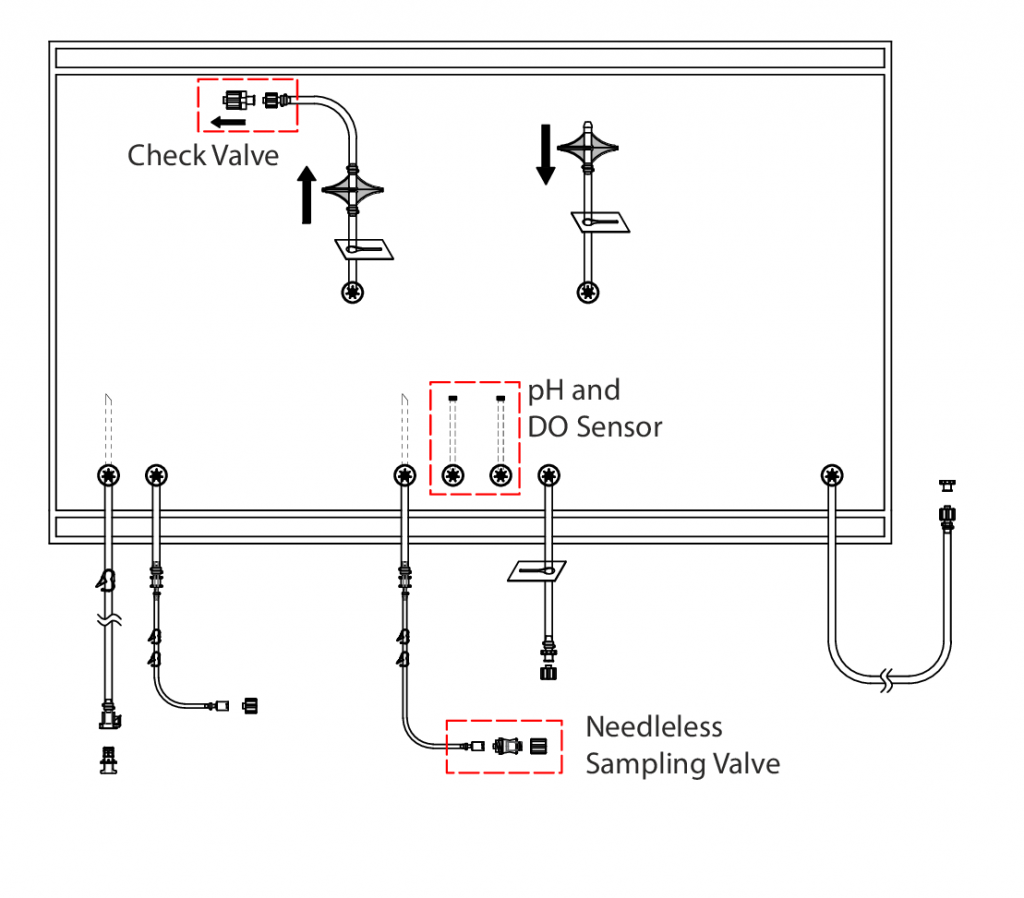

These bags are ideal for the culture of shear sensitive cell lines and can be customized to meet user requirements to eliminate the risk of cross contamination and ease operations. AseptiWave Bioreactors are also available with an optical pH Sensor and DO Sensor for high accuracy and optimal process control embedded on the bag.

Applications

- Cell Culture

- Expansion of anchorage dependent cells such as epidermal and connective tissue cells

- Small scale expansion of stem cells

- Inoculum propagation

- Development and manufacture of

- Therapeutic protein

- Monoclonal Antibodies (mAbs)

- Expansion of CAR T cells for cell therapy