Bio-pharmaceutical industry is involved in development and manufacture of therapeutic drug proteins and monoclonal antibiotics using mammalian cell expression systems, a vital and constantly developing technology.

Cultured cells from mammalian cell expression systems, ranging from a few mL to a few liters in shaker flasks, cell factories and small bioreactors to thousands of liters in large bioreactors, deliver extracellular protein and need to be harvested and clarified for downstream processing to obtain the purified protein of interest. Cell culture clarification is necessary to protect highly sensitive and expensive downstream processes such as diafiltration, ultrafiltration and protein chromatography, and is a challenging task as it contains whole cells, cell debris from dead cells as well a whole gamut of proteins from the cellular activity.

Limitations Of Conventional Methods?

Depending upon various factors such as batch volumes, cell densities, cell viability, available process time and downstream purification steps, different clarification techniques such as centrifugation, tangential flow filtration (TFF) and depth filtration are used. Centrifugation may damage the shear sensitive mammalian cells and release undesirable intracellular proteins and DNA along with difficult to remove submicron particles. TFF and depth filters although can help prevent this, have their own limitations related to set up time, passage of cell debris and large flush volumes to remove inherent extractables.

Another major limitation with these clarification techniques is adaptability to small/ micro bioreactors which may result in process bottle necks, especially in cell expression/ clone and media optimization labs, where large number of small bioreactors is used.

Faster Clarification Without Centrifugation and Minimal Setup Time

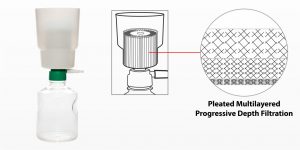

A new vacuum filtration device with a large area pleated multi-layered progressive depth micro-glass fibre filter as it beats this challenge to achieve maximum clarification efficiency with minimal product disruption. This ready to use harvester funnel complete with a receiver bottle is specially designed to filter up to 1 litre of cell harvests within few minutes as compared to hours by centrifugation. It provides effective protection to downstream 0.2um sterilizing filters with its high loading capacity for whole cells and high retention efficiency for cell fragments, organelles, colloids and lipids.

This revolutionary technology has proven its mettle in a high productivity cell expression lab with Human Embryo Kidney (HEK) and Chinese Hamster Ovary (CHO) cell harvests with high cell densities of up to 6 million cells/mL and cell viabilities as low as 80%.

Finding optimal utility in primary clarification of up to 1 litre mammalian cell harvests from small bioreactors, it empowers the process owner with the ability to turn cell harvest to sterile filtrate within minutes by using it in combination with easily available 0.2 micron vacuum filters.

Click here to know more about this futuristic product along with other innovative large area vacuum filters for your lab.